When it comes to terrazzo floors, understanding the intricacies of crystallization can be the key to maintaining their timeless elegance and resilience. The process of terrazzo crystallization involves more than just surface-level shine; it delves into the very composition of the flooring material. By unlocking the mysteries behind this transformative treatment, you will gain insights that could revolutionize your approach to terrazzo floor care.

Key Takeaways

Contents

- 1 Key Takeaways

- 2 What Is Terrazzo Crystallization?

- 3 Benefits of Terrazzo Crystallization

- 4 How Does Crystallization Work?

- 5 Choosing the Right Crystallization Products

- 6 Preparing Terrazzo for Crystallization

- 7 Applying the Crystallization Solution

- 8 Buffing and Polishing Techniques

- 9 Maintenance Tips for Crystallized Terrazzo

- 10 Common Mistakes to Avoid

- 11 Professional Vs. DIY Crystallization

- 12 Frequently Asked Questions

- 12.1 Can Terrazzo Crystallization Be Done on Outdoor Surfaces?

- 12.2 Does Terrazzo Crystallization Make Floors More Slippery?

- 12.3 Are There Environmentally Friendly Crystallization Products Available?

- 12.4 Can Terrazzo Crystallization Fix Deep Scratches and Stains?

- 12.5 How Long Does Crystallization Treatment Last Before Needing Reapplication?

- Terrazzo crystallization involves applying a chemical solution to create a durable, shiny surface.

- The process enhances scratch resistance, improves appearance, and prolongs terrazzo lifespan.

- Thorough cleaning and proper application are crucial for successful crystallization.

- Buffing and polishing with diamond discs bring out the terrazzo's natural shine.

- Regular maintenance with terrazzo-specific cleaners and occasional reapplication ensures long-lasting results.

What Is Terrazzo Crystallization?

Terrazzo crystallization is a specialized process used for restoring and maintaining the luster of terrazzo floors.

This technique involves the application of a chemical solution containing fluorosilicate/potassium fluosilicate onto the terrazzo surface. The solution reacts with the calcium carbonate in the terrazzo, creating a chemical reaction that forms a hard, crystalline surface layer.

This layer helps in filling in any small scratches or imperfections, resulting in a smooth and shiny finish.

During the crystallization process, a floor machine with steel wool pads is used to work the chemical solution into the terrazzo surface.

This mechanical action aids in the formation of the crystalline layer by evenly distributing the solution across the floor.

As the solution dries and hardens, it creates a protective barrier that enhances the durability and appearance of the terrazzo floor.

Terrazzo crystallization is a crucial step in terrazzo floor maintenance, as it not only restores the floor's shine but also helps in prolonging its lifespan.

Benefits of Terrazzo Crystallization

Enhancing the resilience and aesthetic appeal of your terrazzo floors, crystallization presents a range of benefits that contribute to the longevity and visual allure of the surface.

One significant advantage is the increased hardness and durability it provides. By forming a protective layer on the surface, crystallization helps to prevent wear and tear, reducing the need for frequent maintenance.

Additionally, this process enhances the scratch resistance of the terrazzo, making it more resilient to daily foot traffic and other sources of abrasion.

Furthermore, terrazzo crystallization improves the overall appearance of the flooring.

It creates a glossy finish that not only enhances the natural beauty of the terrazzo but also makes it easier to clean and maintain.

The enhanced shine and clarity achieved through crystallization can elevate the aesthetic appeal of any space, making it look more polished and sophisticated.

How Does Crystallization Work?

Utilizing a chemical reaction process, crystallization works by transforming the surface of terrazzo floors into a hardened and glossy finish. This process involves the application of a crystallization product that reacts with the calcium carbonate in the terrazzo to create a durable and shiny surface. The chemical reaction forms a crystalline structure on the surface, enhancing its strength and appearance. Here's a breakdown of how the crystallization process works:

| Step | Description |

|---|---|

| Preparation | Clean the terrazzo surface thoroughly to remove dirt and residue. |

| Application | Apply the crystallization product evenly across the floor surface. |

| Mechanical Agitation | Buff the surface using a floor machine equipped with appropriate pads to promote the crystallization process. |

| Drying | Allow the product to dry and react with the terrazzo, forming a protective and glossy layer. |

| Polishing | Polish the surface to enhance the shine and durability of the terrazzo floor. |

Choosing the Right Crystallization Products

To ensure optimal results in the terrazzo crystallization process, selecting the appropriate crystallization products is paramount.

When choosing these products, consider factors like the type of terrazzo surface, its level of wear, and the desired outcome. Look for crystallization products specifically designed for terrazzo to ensure compatibility and effectiveness.

For standard terrazzo floors, a traditional crystallization product containing a blend of crystalline compounds can be suitable.

These products work by chemically reacting with the calcium carbonate present in terrazzo to create a durable, glossy finish.

However, for more delicate terrazzo surfaces or those with specific requirements, specialized crystallization products may be necessary.

When selecting a product, consider its pH level, abrasiveness, and application method.

Some products may require dilution with water, while others come ready-to-use.

Always follow the manufacturer's instructions for the best results.

Experimenting with different products on a small test area can help determine the most effective option for your terrazzo surface.

Preparing Terrazzo for Crystallization

To properly prepare terrazzo for crystallization, it's essential to begin with a thorough cleaning process to remove any dirt, debris, or previous coatings that may hinder the effectiveness of the crystallization treatment.

Start by sweeping or vacuuming the surface to eliminate loose particles. Follow this by mopping with a neutral pH cleaner to get rid of any remaining residues. If the terrazzo has stubborn stains, consider using a specialized terrazzo cleaner to ensure a pristine surface.

Once the terrazzo is clean and dry, inspect the surface for any damages that may need repair before proceeding with the crystallization process.

Fill any cracks or holes with an appropriate filler and allow it to cure completely. Ensure that the terrazzo surface is level and smooth to achieve optimal results during crystallization.

Lastly, if there are any wax or acrylic coatings present, strip them off using a suitable remover to ensure proper bonding of the crystallization solution to the terrazzo surface.

Proper preparation is the key to a successful terrazzo crystallization process.

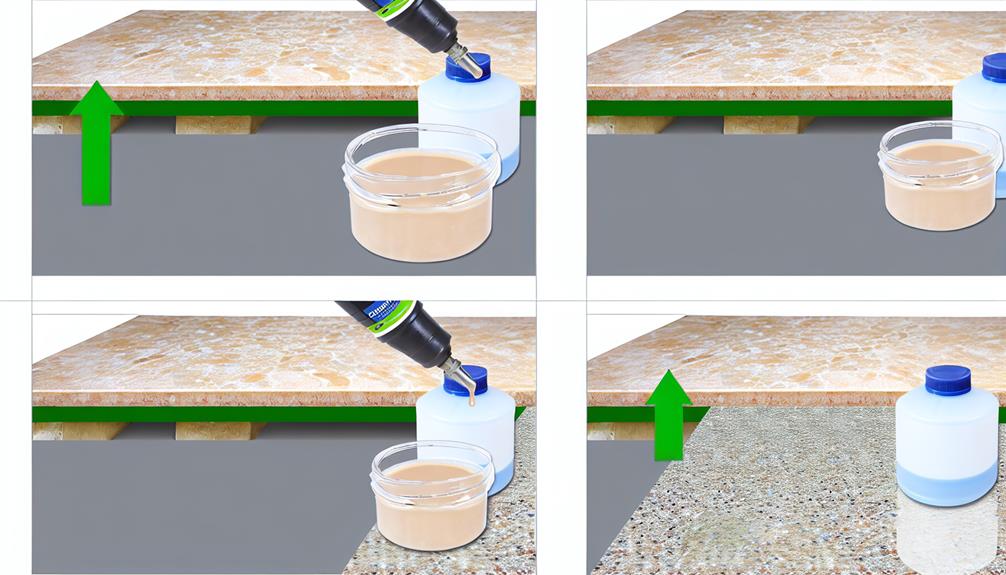

Applying the Crystallization Solution

Applying the crystallization solution is a critical step in enhancing the durability and shine of terrazzo surfaces.

Prior to application, ensure the terrazzo floor is clean and dry.

Using a low-speed floor machine fitted with a steel wool pad or a crystallization-specific pad, begin by spreading the crystallization solution evenly across the surface.

Work in small sections, overlapping each pass to guarantee uniform coverage. Apply the solution sparingly, avoiding puddles or excess buildup.

The key is to create a thin, even film over the terrazzo.

Allow the solution to dry completely, forming a crystalline structure on the surface.

This process may take some time depending on the product used and environmental conditions.

Once the solution has dried, carefully inspect the terrazzo for any missed spots or uneven coverage.

If needed, reapply the crystallization solution to those areas.

Remember, proper application is crucial for achieving a durable and glossy finish.

Mastering this step will set the foundation for the subsequent buffing and polishing techniques.

Buffing and Polishing Techniques

For achieving a flawless finish on terrazzo surfaces, mastering the buffing and polishing techniques is essential.

Begin by ensuring your terrazzo surface is clean and free of any debris. Use a floor machine equipped with diamond-impregnated discs for effective polishing.

Start with a low-grit diamond disc, gradually progressing to higher grits for a smoother finish. Remember to work in small sections, overlapping each pass to avoid missing spots. Apply water during the polishing process to reduce dust and keep the surface cool.

Keep the machine moving at a consistent pace to prevent uneven polishing. Once the desired level of smoothness is achieved, switch to a resin-bonded diamond polishing pad for the final polish.

This step will bring out the terrazzo's natural shine and enhance its durability. Regularly check the condition of your polishing equipment to ensure optimal performance.

Mastering these buffing and polishing techniques will result in a beautifully restored terrazzo surface that shines with perfection.

Maintenance Tips for Crystallized Terrazzo

Maintaining the brilliance of crystallized terrazzo requires a strategic approach that combines regular cleaning practices with specialized care techniques.

To keep your terrazzo floors looking their best, start by implementing a daily cleaning routine using a neutral pH cleaner and a microfiber mop to remove dust and debris.

Weekly, use a terrazzo-specific cleaner to maintain the crystallized surface. For heavier soiling, consider a deep cleaning using a terrazzo restorer to renew the shine.

In addition to routine cleaning, it's essential to periodically reapply a crystallization solution to enhance the gloss and durability of the terrazzo.

This process helps fill in any surface imperfections and creates a protective barrier against stains and wear. When applying the crystallization solution, ensure the terrazzo surface is clean and dry for optimal adhesion.

Regularly inspect your crystallized terrazzo for any signs of wear or damage, addressing any issues promptly to prevent further deterioration.

Common Mistakes to Avoid

To ensure the longevity and luster of your crystallized terrazzo floors, it's crucial to be aware of common mistakes that can undermine their beauty and durability.

One common mistake to avoid is using harsh cleaning chemicals that can damage the crystallized surface. These chemicals can strip away the protective layer and dull the shine of the terrazzo.

Additionally, failing to properly rinse the floor after cleaning can leave behind residue that accumulates over time, leading to a cloudy appearance.

Another mistake to steer clear of is using abrasive tools or scrub pads when cleaning the terrazzo. These can scratch the surface and wear down the crystallized layer, diminishing its effectiveness in protecting the floor.

Furthermore, neglecting regular maintenance and reapplication of the crystallization treatment can result in a loss of shine and leave the terrazzo vulnerable to stains and wear.

Professional Vs. DIY Crystallization

When considering terrazzo crystallization, the decision between opting for professional services or attempting a DIY approach can significantly impact the outcome of the process.

Professional crystallization services offer expertise, specialized equipment, and a deep understanding of the intricacies involved in the crystallization process. Professionals are trained to assess the specific needs of your terrazzo surface, tailor the crystallization method accordingly, and ensure a high-quality, long-lasting finish.

DIY crystallization, on the other hand, requires meticulous planning, thorough knowledge of the terrazzo composition, and the correct application of crystallization products.

While it can be a cost-effective option, DIY crystallization carries the risk of improper application, leading to streaks, uneven finish, or even damage to the terrazzo surface. Without the experience and skill of a professional, achieving optimal results with a DIY approach can be challenging.

Frequently Asked Questions

Can Terrazzo Crystallization Be Done on Outdoor Surfaces?

Yes, you can perform terrazzo crystallization on outdoor surfaces. It enhances durability, provides a glossy finish, and protects against weathering. The process involves applying a crystallization agent and mechanically polishing the terrazzo to achieve optimal results.

Does Terrazzo Crystallization Make Floors More Slippery?

Terrazzo crystallization can increase slipperiness on floors. Proper maintenance and regular cleaning are crucial to manage this. Understanding the process and using appropriate products can help control slip hazards and maintain a safe environment.

Are There Environmentally Friendly Crystallization Products Available?

When looking for environmentally friendly terrazzo crystallization products, you may find options that prioritize sustainability without compromising effectiveness. These solutions can help maintain your floors while minimizing environmental impact, providing a balance between performance and eco-consciousness.

Can Terrazzo Crystallization Fix Deep Scratches and Stains?

Yes, terrazzo crystallization can effectively address deep scratches and stains. It works by restoring the surface through a chemical reaction that creates a durable, glossy finish. This process is commonly used in terrazzo restoration projects for remarkable results.

How Long Does Crystallization Treatment Last Before Needing Reapplication?

Terrazzo crystallization treatments typically last 1-2 years before reapplication is needed. Factors like foot traffic, maintenance, and cleaning methods can impact this duration. Regular assessments and a maintenance schedule can help extend the treatment's effectiveness.