When it comes to terrazzo floors, the crystallization process is a crucial step in achieving that coveted shine and durability. Imagine a transformation occurring at a molecular level, enhancing both the aesthetics and longevity of your flooring investment. But how exactly does this process work, and what sets it apart from traditional methods? Let's explore the intricate dance between chemistry and craftsmanship that makes terrazzo crystallization a game-changer for maintaining stunning surfaces.

Key Takeaways

Contents

- 1 Key Takeaways

- 2 Understanding Terrazzo Crystallization

- 3 How Crystallization Enhances Terrazzo Shine

- 4 Benefits of Terrazzo Crystallization

- 5 The Science Behind Crystallization

- 6 Steps in the Crystallization Process

- 7 Comparing Crystallization to Other Methods

- 8 Maintaining Terrazzo After Crystallization

- 9 Factors Influencing Crystallization Results

- 10 Professional Vs. DIY Crystallization

- 11 Longevity of Crystallized Terrazzo Floors

- 12 Frequently Asked Questions

- 12.1 Can Terrazzo Crystallization Be Applied to Outdoor Terrazzo Surfaces?

- 12.2 Does Crystallization Make Terrazzo Floors More Slippery?

- 12.3 How Long Does It Take for Terrazzo Crystallization to Dry?

- 12.4 Can Terrazzo Crystallization Be Done on Colored Terrazzo Floors?

- 12.5 Is Terrazzo Crystallization Suitable for High-Traffic Areas Like Commercial Spaces?

- Surface must be clean and stripped before applying crystallization chemicals.

- Crystallization solution promotes crystal growth for durability and gloss.

- New crystals bind with calcium carbonate for enhanced protection.

- Crystalline layer increases wear, stain resistance, and gloss retention.

- Buffing after application ensures a smooth, glossy finish.

Understanding Terrazzo Crystallization

Terrazzo crystallization is a process essential in maintaining the durability and appearance of terrazzo flooring.

This method involves a chemical reaction between a crystallizing agent and the calcium carbonate present in the terrazzo surface. The crystallizing agent creates a chemical bond with the calcium carbonate, forming a protective layer that enhances the floor's resistance to wear, scratches, and stains.

During the terrazzo crystallization process, the surface is first thoroughly cleaned and stripped of any coatings or residues.

Then, a crystallizing agent is applied evenly across the floor and worked into the surface using a floor machine with a steel wool pad or brush. This mechanical action helps distribute the crystallizing agent uniformly, ensuring a consistent protective layer formation.

Terrazzo crystallization is a crucial step in terrazzo maintenance as it not only strengthens the surface but also improves its aesthetic appeal by enhancing the natural shine and color of the terrazzo.

Proper application of the crystallizing agent and meticulous buffing are key to achieving optimal results and prolonging the lifespan of the terrazzo flooring.

How Crystallization Enhances Terrazzo Shine

To enhance the shine of terrazzo flooring, crystallization plays a crucial role by creating a protective layer that improves the surface's durability and aesthetic appeal.

Through a chemical reaction between the crystallizing agent and the calcium carbonate in the terrazzo matrix, a hard, glossy layer is formed on the surface. This layer not only enhances the shine but also provides a barrier against wear and tear, making the terrazzo more resistant to scratches, stains, and other damage.

Crystallization achieves this by filling in the pores and micro-fissures present in the terrazzo, creating a smoother surface that reflects light more evenly, resulting in a higher level of gloss.

Additionally, the crystallization process increases the density of the terrazzo surface, making it less prone to penetration by liquids and dirt. This improved surface quality not only enhances the visual appeal of the terrazzo but also simplifies maintenance, as the smoother surface is easier to clean and maintain over time.

Benefits of Terrazzo Crystallization

By enhancing the durability and aesthetic appeal of terrazzo flooring, crystallization offers a range of benefits that go beyond just improving its shine.

Through the crystallization process, terrazzo flooring gains several advantages:

- Enhanced Wear Resistance: The crystallization of terrazzo creates a protective layer that increases its resistance to wear and abrasion, prolonging the lifespan of the flooring.

- Improved Stain Resistance: The crystallized surface of terrazzo becomes more resistant to stains, making it easier to clean and maintain over time.

- Increased Gloss Retention: Crystallization helps the terrazzo flooring maintain its glossy appearance for longer periods, reducing the need for frequent polishing.

- Enhanced Color Vibrancy: The process of crystallization enhances the natural colors and patterns of the terrazzo, giving it a vibrant and lustrous finish that adds to the overall aesthetic appeal.

These benefits make terrazzo crystallization a valuable investment for ensuring the longevity and beauty of your flooring.

The Science Behind Crystallization

Crystallization, a chemical process employed in the treatment of terrazzo flooring, involves the transformation of the surface at a molecular level. During this process, the application of a crystallization solution promotes the growth of new crystals on the terrazzo surface, resulting in enhanced durability and a glossy finish. The science behind crystallization lies in the reaction between the solution and the calcium carbonate in the terrazzo, forming a hard and protective crystalline layer.

To better understand the intricacies of this process, let's delve into the key elements involved:

| Element | Description | Role |

|---|---|---|

| Crystallization Solution | Chemical solution applied to the terrazzo surface | Initiates crystal growth |

| Calcium Carbonate | Primary component of terrazzo flooring | Binds with solution to form new crystals |

| Crystal Formation | Growth of new crystals on the surface | Enhances durability and provides glossiness |

| Protective Layer | Hard crystalline layer formed after the process | Improves resistance to wear and tear |

Understanding these elements is crucial in mastering the science behind terrazzo crystallization.

Steps in the Crystallization Process

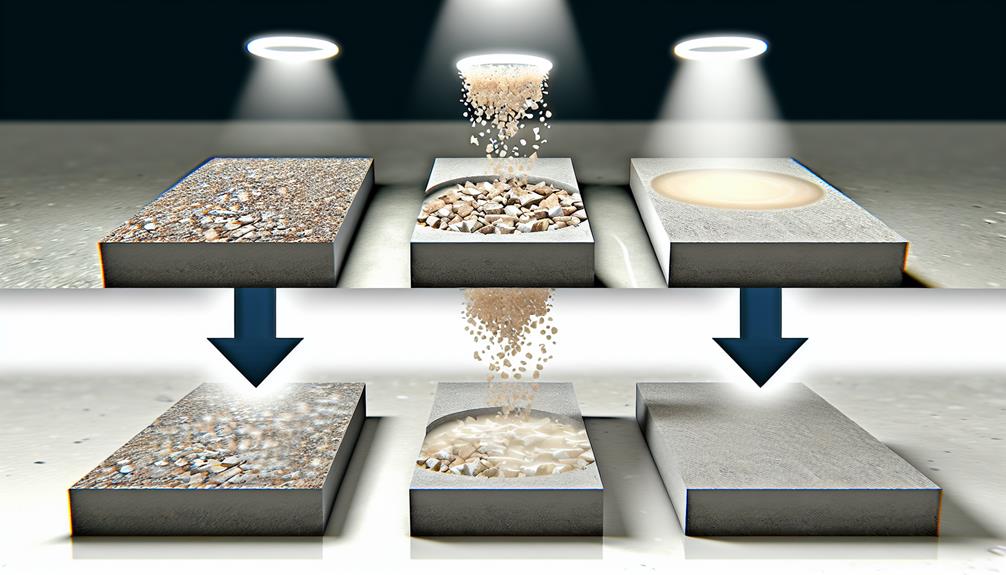

In the treatment of terrazzo flooring, the crystallization process involves a series of distinct steps that are essential for achieving the desired outcome.

To successfully crystallize terrazzo, you must follow these critical steps:

– Surface Preparation: Begin by ensuring the terrazzo surface is thoroughly clean and free of any debris or contaminants.

This step is crucial as it sets the foundation for the crystallization process.

– Application of Crystallization Chemicals: Next, apply the specialized crystallization chemicals evenly across the terrazzo surface.

These chemicals play a vital role in the transformation of the surface into a durable and glossy finish.

– Mechanical Polishing: Utilize a high-speed burnisher or polishing machine to mechanically work the crystallization chemicals into the terrazzo surface.

This action aids in activating the chemical reaction necessary for achieving the desired crystallized effect.

– Buffing and Finishing: Finally, buff the terrazzo surface to a brilliant shine.

This step ensures a smooth and reflective finish, enhancing the overall appearance and durability of the terrazzo flooring.

Comparing Crystallization to Other Methods

Comparing terrazzo crystallization to alternative methods of surface treatment reveals distinct differences in durability, glossiness, and maintenance requirements.

Terrazzo crystallization involves a chemical reaction that creates a protective layer on the surface, enhancing its durability significantly compared to traditional sealers or coatings.

This crystalline layer also imparts a high level of glossiness that's long-lasting and resistant to wear and abrasion, unlike topical coatings that may wear off over time.

In terms of maintenance, terrazzo crystallization typically requires less frequent reapplication compared to waxing or sealing methods.

The crystallized surface is easier to clean and maintain, reducing the need for frequent reapplications and specialized cleaning products.

Additionally, the crystallization process can improve the overall hardness of the terrazzo surface, making it more resistant to scratches and stains compared to other surface treatment methods.

Maintaining Terrazzo After Crystallization

After terrazzo crystallization, maintaining the surface becomes crucial for preserving its durability and glossiness.

To ensure the longevity of your terrazzo flooring, follow these maintenance tips:

- Regular Cleaning: Use a neutral pH cleaner and a soft mop to remove dirt and debris. Avoid acidic or abrasive cleaners that can damage the crystallized surface.

- Preventive Measures: Place doormats at entryways to reduce the amount of grit and dirt brought onto the terrazzo surface, which can cause scratches.

- Periodic Buffing: Schedule periodic buffing sessions to maintain the terrazzo's shine and smoothness. This helps in removing minor scratches and restoring the gloss.

- Professional Maintenance: Consider hiring professionals for deep cleaning and reapplication of the crystallization process to rejuvenate the terrazzo surface.

Factors Influencing Crystallization Results

For optimal terrazzo crystallization results, various factors play a significant role in determining the outcome.

The first crucial factor is the type and quality of the crystallization product used. Different products have varying chemical compositions and properties that can impact the final result.

Secondly, the preparation of the terrazzo surface before crystallization is essential. Proper cleaning and removal of any coatings or residues are necessary for the crystallization process to be effective.

The condition of the terrazzo surface itself, including its hardness and porosity, also influences the crystallization outcome. Additionally, environmental factors such as temperature and humidity can affect the crystallization process.

The expertise of the individual performing the crystallization is another critical factor. Proper technique, timing, and application methods are vital for achieving the desired results.

Professional Vs. DIY Crystallization

When considering terrazzo crystallization, the choice between professional services and do-it-yourself (DIY) methods is a critical decision that can significantly impact the outcome.

Professional Services

- Utilize specialized equipment for precise application.

- Experienced professionals understand the intricacies of the process.

- Guarantees a high-quality finish due to expertise.

- Often come with warranties for the service provided.

Choosing professional services ensures a meticulous and expertly executed crystallization process.

DIY Methods

- Requires thorough research and understanding of the technique.

- Risk of improper application leading to subpar results.

- Cost-effective for individuals with skills in terrazzo maintenance.

- Provides a hands-on experience for those inclined towards DIY projects.

Opting for a DIY approach demands attention to detail and a willingness to learn and execute the process correctly.

Ultimately, the decision between professional services and DIY methods hinges on your expertise, resources, and desired outcome.

Longevity of Crystallized Terrazzo Floors

The longevity of crystallized terrazzo floors is a key aspect to consider when evaluating the effectiveness of terrazzo crystallization.

When properly executed, terrazzo crystallization can significantly enhance the durability and lifespan of the flooring. The crystallization process creates a hardened surface by forming a chemical reaction with the calcium carbonate in the terrazzo, resulting in a protective layer that helps resist scratches, stains, and wear over time.

The longevity of crystallized terrazzo floors is influenced by various factors, including the quality of the initial terrazzo installation, the application of the crystallization process, and the regular maintenance practices employed.

Proper cleaning, buffing, and periodic reapplication of the crystallization treatment can extend the lifespan of the terrazzo floors.

It is essential to follow manufacturer guidelines and recommendations for maintenance to ensure the longevity of crystallized terrazzo floors.

Frequently Asked Questions

Can Terrazzo Crystallization Be Applied to Outdoor Terrazzo Surfaces?

Yes, you can apply terrazzo crystallization to outdoor terrazzo surfaces. This process enhances durability and provides a glossy finish. It is recommended for its ability to protect against weathering and maintain the terrazzo's aesthetic appeal.

Does Crystallization Make Terrazzo Floors More Slippery?

You may wonder if terrazzo floors become more slippery with crystallization. Crystallization can indeed increase slipperiness due to the smoother surface it creates. To mitigate this, proper maintenance and anti-slip treatments are recommended.

How Long Does It Take for Terrazzo Crystallization to Dry?

After terrazzo crystallization, drying times vary based on environmental conditions. Generally, it takes 24-48 hours for the process to fully dry. Factors like temperature, humidity, and ventilation influence drying speed. Ensure optimal conditions for efficient results.

Can Terrazzo Crystallization Be Done on Colored Terrazzo Floors?

Yes, terrazzo crystallization can be done on colored terrazzo floors. The process enhances the vibrancy and durability of colored terrazzo, providing a glossy finish that accentuates the floor's unique hues and patterns.

Is Terrazzo Crystallization Suitable for High-Traffic Areas Like Commercial Spaces?

In high-traffic areas like commercial spaces, terrazzo crystallization is a suitable method to enhance durability and maintain a polished finish. This process strengthens the surface, increasing resistance to wear and maintaining aesthetic appeal in busy environments.