When aiming to achieve terrazzo vitrification, you must meticulously follow a series of precise steps that will transform your terrazzo surface into a gleaming masterpiece. Each stage, from the initial assessment to the final sealing process, plays a crucial role in attaining that coveted mirror-like finish. By understanding the intricacies of this method, you can elevate the appeal of your terrazzo floors to a whole new level. But what sets apart a standard terrazzo finish from a vitrified one? That's where the magic truly happens.

Key Takeaways

Contents

- 1 Key Takeaways

- 2 Surface Preparation

- 3 Cleaning and Degreasing

- 4 Application of Vitrification Chemical

- 5 Buffing and Polishing

- 6 Sealing the Terrazzo Surface

- 7 Final Inspection and Touch-Ups

- 8 Maintaining Vitrified Terrazzo Floors

- 9 Troubleshooting Common Issues

- 10 Benefits of Terrazzo Vitrification

- 11 Professional Vitrification Services

- 12 Frequently Asked Questions

- 12.1 Can Terrazzo Vitrification Be Applied to Outdoor Surfaces?

- 12.2 How Long Does a Vitrified Terrazzo Surface Last?

- 12.3 Can Vitrification Be Applied to Colored Terrazzo Floors?

- 12.4 Is It Possible to Remove Vitrification From a Terrazzo Surface?

- 12.5 Are There Any Health or Environmental Concerns With Terrazzo Vitrification Chemicals?

- Thoroughly clean and degrease the terrazzo surface before applying vitrification chemicals.

- Prepare and apply the vitrification solution evenly, following manufacturer instructions.

- Buff and polish the surface with abrasive pads to achieve a high-gloss finish.

- Seal the terrazzo with a quality sealer to protect and maintain the vitrified surface.

- Regular maintenance, including cleaning and resealing, is essential for long-lasting results.

Surface Preparation

Before beginning the terrazzo vitrification process, surface preparation is crucial to ensure optimal results.

The first step involves assessing the current state of the terrazzo surface. Inspect for any cracks, chips, or imperfections that need to be addressed before proceeding.

Next, thoroughly clean the surface to remove any dirt, dust, or debris that could interfere with the vitrification process. Utilize a high-quality cleaner specifically designed for terrazzo to ensure effective removal of all contaminants.

Once the surface is clean, it's essential to ensure that it's completely dry before proceeding further. Moisture can negatively impact the vitrification process, leading to uneven results.

After confirming the surface is dry, inspect for any remaining stains or discoloration that may require additional treatment. Address these issues using appropriate cleaning techniques or products.

Cleaning and Degreasing

Assess the terrazzo surface for any cracks, chips, or imperfections before moving on to the cleaning and degreasing phase.

Proper cleaning and degreasing are crucial steps in preparing the terrazzo surface for vitrification.

Begin by removing any loose debris or dust using a vacuum or broom.

Follow this by washing the surface with a neutral pH cleaner to eliminate any dirt, grime, or residues.

For degreasing, especially in areas prone to oil or grease buildup, utilize a specialized degreaser to ensure complete removal of contaminants.

Scrubbing with a brush may be necessary for stubborn stains or grease spots.

Rinse the surface thoroughly to remove any remaining cleaning agents.

It is essential to allow the terrazzo surface to dry completely before proceeding to the next vitrification steps.

Proper cleaning and degreasing guarantee a pristine surface for the vitrification process, allowing for optimal adhesion and a flawless finish.

Application of Vitrification Chemical

To initiate the process of applying the vitrification chemical to the terrazzo surface, it's imperative to ensure that the surface has been thoroughly cleaned and degreased as per the previous steps.

The application of the vitrification chemical is a critical step in achieving the desired glossy finish and long-lasting protection for the terrazzo flooring.

Begin by preparing the vitrification chemical solution according to the manufacturer's instructions.

Using a clean mop or applicator, apply the solution evenly onto the terrazzo surface. It's important to work in small sections to ensure uniform coverage.

Allow the vitrification chemical to dry completely on the surface.

This drying process is crucial for the chemical to bond effectively with the terrazzo and create a durable, protective layer.

Once dried, the surface can be buffed and polished to reveal the desired high-gloss finish.

Remember to follow all safety precautions when handling the vitrification chemical and ensure proper ventilation in the workspace.

This meticulous application process will result in a beautifully vitrified terrazzo surface that's both stunning and resilient.

Buffing and Polishing

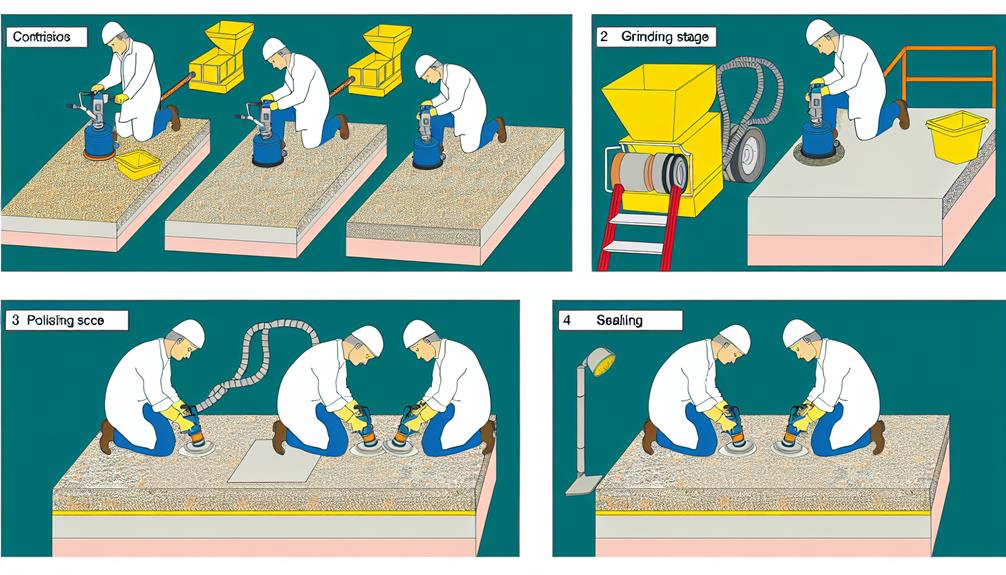

When buffing and polishing terrazzo flooring, the process involves using specialized equipment and techniques to enhance the surface's appearance and durability.

Buffing is the initial stage, where a coarse abrasive pad is employed to remove any surface imperfections and level the terrazzo.

This step prepares the floor for polishing, which follows with finer grit pads to achieve a smooth, glossy finish.

Polishing terrazzo is a meticulous process that requires attention to detail.

Each polishing pad is designed to gradually refine the surface, bringing out the terrazzo's inherent beauty.

The final polishing stages involve using diamond impregnated pads to give the floor a brilliant shine.

Proper technique and consistent pressure are crucial to ensure an even finish across the entire surface.

Buffing and polishing not only enhance the aesthetic appeal of terrazzo flooring but also contribute to its longevity.

The smooth, glossy finish achieved through this process not only looks stunning but also provides a protective layer that helps prevent wear and tear.

Mastering the art of buffing and polishing is essential in achieving a flawless terrazzo surface.

Sealing the Terrazzo Surface

After completing the buffing and polishing process to enhance the appearance and durability of your terrazzo flooring, the next step is sealing the surface.

Sealing the terrazzo surface is crucial to protect it from stains, scratches, and daily wear and tear.

1. Surface Preparation: Before applying the sealer, ensure the terrazzo surface is thoroughly clean and free of any debris, dust, or residues. Use a neutral pH cleaner to remove all contaminants and allow the surface to dry completely before proceeding with the sealing process.

2. Choosing the Right Sealer: Select a high-quality terrazzo sealer that's specifically designed for the type of terrazzo flooring you have.

Consider factors like the porosity of the terrazzo, the level of traffic it receives, and the desired finish (matte, semi-gloss, or high-gloss).

3. Application Technique: Apply the sealer evenly using a clean microfiber applicator or a low-pressure sprayer.

Follow the manufacturer's instructions regarding the number of coats needed and the drying times between coats to achieve optimal results.

Final Inspection and Touch-Ups

Now, as you approach the final stages of sealing your terrazzo flooring, conducting a meticulous inspection and addressing any necessary touch-ups is paramount to ensure a flawless finish.

Begin by inspecting the entire surface for any imperfections such as bubbles, streaks, or uneven areas. Use a bright light at a low angle to highlight any flaws that may need correction.

Address any issues by carefully sanding or buffing the affected areas to blend them seamlessly with the rest of the floor. Ensure that the touch-up materials match the surrounding surface in color and texture to maintain a uniform appearance.

After addressing the touch-ups, conduct a final inspection to verify that all corrections have been made satisfactorily. Check for consistency in sheen and color across the entire floor.

Pay close attention to edges and corners, as these areas are often overlooked but can significantly impact the overall finish. Once you're satisfied with the results, your terrazzo flooring is ready for use.

Maintaining Vitrified Terrazzo Floors

To maintain vitrified terrazzo floors, regular cleaning and proper care are essential.

These exquisite floors require specific attention to ensure their longevity and luster.

Follow these key steps:

1. Routine Cleaning: Regularly sweep or vacuum the floor to remove dirt and debris that can scratch the surface.

Use a neutral pH cleaner and a damp mop for weekly cleaning to keep the terrazzo looking pristine.

2. Avoid Harsh Chemicals: Refrain from using acidic or abrasive cleaners as they can damage the vitrified surface.

Opt for pH-neutral cleaners that are gentle yet effective in maintaining the terrazzo's shine.

3. Periodic Maintenance: Schedule periodic resealing and polishing to rejuvenate the terrazzo's appearance.

This will help protect the surface from stains and wear, keeping your floors looking like new for years to come.

Troubleshooting Common Issues

When troubleshooting common issues with vitrified terrazzo floors, precision is key to identifying and addressing problems effectively.

One common issue is hazing, which appears as a cloudy or milky layer on the surface. This can be caused by improper cleaning agents or insufficient rinsing.

To resolve this, thoroughly clean the floor with a neutral pH cleaner and ensure proper rinsing.

Another issue is spalling, where the surface chips or flakes off. Spalling can occur due to improper installation, excessive moisture, or freeze-thaw cycles.

To tackle this problem, repair the damaged areas by re-embedding the chips and applying a compatible terrazzo patching material.

Additionally, efflorescence, a white powdery deposit, may occur due to water infiltration or soluble salts.

Remove efflorescence with a mild acidic solution followed by rinsing.

Benefits of Terrazzo Vitrification

During the process of terrazzo vitrification, the surface of the terrazzo floor is treated with a chemical densifier that penetrates and reacts with the calcium hydroxide in the concrete matrix.

This process offers several benefits that enhance the durability and aesthetics of the terrazzo floor:

- Increased Strength: Vitrification creates a hardened surface by filling in the pores of the terrazzo, making it more resistant to abrasion and impact.

- Enhanced Stain Resistance: The chemical reaction during vitrification reduces the porosity of the terrazzo, making it less susceptible to staining from spills and contaminants.

- Improved Gloss and Clarity: Vitrification results in a high-gloss finish that enhances the natural beauty of the terrazzo, providing a luxurious and visually appealing surface.

Professional Vitrification Services

Professional terrazzo vitrification services are essential for maintaining the quality and longevity of your terrazzo floors.

It's crucial to entrust the vitrification process to skilled professionals who possess the expertise and specialized equipment required for achieving optimal results. These professionals are well-versed in the intricacies of terrazzo maintenance and understand the specific needs of your flooring.

Professional vitrification services typically involve a thorough assessment of the terrazzo surface to determine the appropriate treatment plan.

This may include cleaning the floor to remove any dirt or debris, honing to smooth out imperfections, and finally, applying the vitrification solution to achieve a durable, glossy finish. Additionally, these experts can provide guidance on proper maintenance practices to prolong the effects of vitrification and keep your terrazzo floors looking their best for years to come.

Frequently Asked Questions

Can Terrazzo Vitrification Be Applied to Outdoor Surfaces?

Yes, terrazzo vitrification can be applied to outdoor surfaces. This process enhances durability and provides a glossy finish. It involves grinding, honing, and sealing the terrazzo surface to protect it from weather elements and maintain its aesthetic appeal.

How Long Does a Vitrified Terrazzo Surface Last?

To achieve terrazzo vitrification, the duration of a vitrified terrazzo surface's longevity typically ranges from 10 to 30 years when properly maintained, varying based on factors such as foot traffic, maintenance regimen, and environmental conditions.

Can Vitrification Be Applied to Colored Terrazzo Floors?

Yes, vitrification can enhance the durability and aesthetics of colored terrazzo floors. Through a meticulous process of applying specific chemicals and polishing techniques, the colors are intensified and the surface gains increased strength and resistance to wear.

Is It Possible to Remove Vitrification From a Terrazzo Surface?

Yes, it is possible to remove vitrification from a terrazzo surface through specialized processes like mechanical abrasion or chemical stripping. These methods effectively eliminate the vitrified layer, restoring the natural beauty of the terrazzo beneath.

Are There Any Health or Environmental Concerns With Terrazzo Vitrification Chemicals?

Yes, there are potential health and environmental concerns associated with terrazzo vitrification chemicals. Exposure to these chemicals can pose risks to both human health and the environment if not handled properly. It's crucial to prioritize safety measures.