When it comes to terrazzo polishing, did you know that mastering the 10-step process can elevate your results to a whole new level of perfection? Discover the intricacies of each step, from surface preparation to the final sealant application, that contribute to achieving a flawless finish on your terrazzo surfaces. Understanding these key steps will not only enhance the aesthetic appeal of your terrazzo but also ensure its longevity and durability. So, are you ready to unlock the secrets behind mastering terrazzo polishing like a pro?

Key Takeaways

Contents

- Start with thorough surface preparation for a flawless finish.

- Use proper equipment and diamond tooling for efficient material removal.

- Employ a systematic approach when grinding, honing, and polishing.

- Fill and patch any imperfections with high-quality epoxy filler.

- Apply sealant evenly to protect the terrazzo surface from stains and wear.

Surface Preparation

Before diving into terrazzo polishing, the crucial step of surface preparation must be executed meticulously.

To begin, ensure the surface is clean and free of any debris or coatings. Use a high-quality degreaser to remove any oily residues, followed by a thorough rinse and dry.

Next, inspect the surface for any cracks or holes. Fill these imperfections with a suitable epoxy filler, making sure to level it with the surrounding terrazzo.

Once the filler has cured, proceed to diamond grind the surface using progressively finer grits to achieve a smooth and uniform finish. This step is crucial as it lays the foundation for a flawless polishing process.

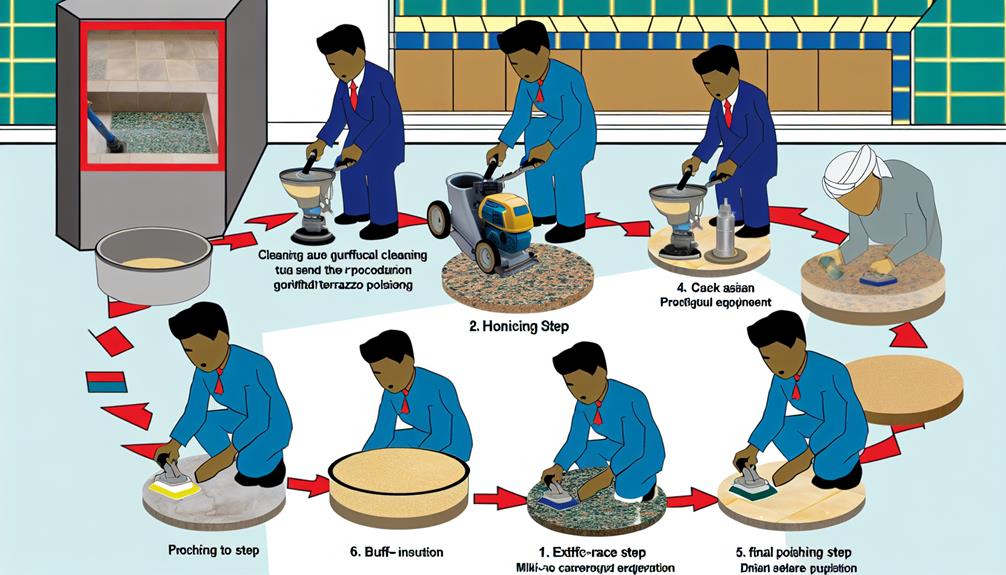

Grinding and Honing

To achieve a professional terrazzo polishing outcome, mastering the process of grinding and honing is essential.

Grinding involves the use of coarse diamond abrasives to remove imperfections and level the surface. This step is crucial as it sets the foundation for a flawless finish.

When honing, finer grit diamonds are used to further smooth the surface and prepare it for polishing. The honing process helps to refine the terrazzo, enhancing its overall appearance and creating a uniform surface ready for the final polishing stages.

During grinding and honing, it's important to maintain a consistent pressure and speed to achieve an even surface.

Proper equipment and diamond tooling selection are paramount to ensure efficient material removal and a uniform finish. Take care to follow a systematic approach, moving in a grid pattern to cover the entire surface evenly.

Filling and Patching

As you progress to the next phase of terrazzo polishing, attention to detail in filling and patching becomes paramount.

Before starting this crucial step, ensure the surface is clean and dry. Begin by examining the terrazzo carefully, identifying any holes, cracks, or imperfections that need attention.

For small holes and cracks, use a high-quality epoxy filler that matches the color of the terrazzo to ensure a seamless finish. Apply the filler using a putty knife, making sure to overfill slightly to compensate for shrinkage.

For larger voids or damaged areas, consider using a terrazzo patching compound. Mix the compound according to the manufacturer's instructions and apply it evenly over the area, using a trowel to level it with the surrounding surface.

Allow ample time for the filler or patching compound to cure completely before proceeding to the next step. Remember, thorough filling and patching are essential for achieving a flawless terrazzo surface ready for the polishing process ahead.

Polishing Techniques

Embark on the path to a truly polished terrazzo surface by delving into the intricate world of polishing techniques.

To achieve a flawless finish, you must first understand the various methods at your disposal. Begin by employing a coarse diamond abrasive to grind away any imperfections, gradually moving to finer grits as the surface smoothes out.

This initial step sets the foundation for a mirror-like shine.

Next, utilize resin diamond pads to further refine the terrazzo surface.

These pads, available in different grit levels, help eliminate scratches left by the initial grinding stage.

Remember, patience is key during this phase as each pass with the resin pads brings you closer to perfection.

Once the surface is adequately refined, switch to a polishing powder to enhance the terrazzo's luster.

Apply the powder evenly and work it into the surface using a floor buffer.

This step adds a dazzling sheen to the terrazzo, elevating its visual appeal.

Mastering these polishing techniques will bring your terrazzo surface to life, showcasing its beauty and durability in the most radiant manner possible.

Final Polishing Steps

For achieving a flawlessly polished terrazzo surface, the final polishing steps are crucial in elevating the shine and overall appearance.

Begin by thoroughly cleaning the surface to remove any debris or residue. Next, using a high-quality polishing compound, work in small sections, applying the compound evenly with a polishing machine. Ensure the machine is set to the correct speed and pressure to avoid damaging the terrazzo.

Gradually increase the speed as you polish to achieve a glossy finish.

Once the initial polishing is complete, inspect the surface for any imperfections. If needed, repeat the polishing process in specific areas until the desired shine is achieved.

After the final polish, clean the surface again to remove any remaining polishing compound. Finally, buff the terrazzo with a clean, soft pad to enhance the shine further.

Applying Sealant

When it comes to perfecting the terrazzo polishing process, the application of sealant plays a vital role in preserving the shine and durability of the surface.

After completing the final polishing steps, applying sealant is crucial for protecting the terrazzo surface from stains, water damage, and daily wear and tear.

To begin, ensure the surface is clean and dry before applying the sealant.

Use a high-quality sealant specifically designed for terrazzo surfaces.

Apply the sealant evenly using a clean microfiber cloth or a paint roller for larger areas.

Allow the first coat to dry completely before applying a second coat to enhance the protective layer.

Once the sealant has dried thoroughly, buff the surface with a clean, dry microfiber cloth to achieve a glossy finish.

Regularly maintain the sealed terrazzo surface by cleaning it with a pH-neutral cleaner and reapplying the sealant as needed to prolong its longevity and luster.

Mastering the application of sealant is essential for preserving the beauty and resilience of your terrazzo floors or countertops.

Frequently Asked Questions

Can Terrazzo Polishing Be Done on Vertical Surfaces Like Walls?

Yes, terrazzo polishing can be done on vertical surfaces like walls. It requires specialized equipment and techniques to ensure a smooth and uniform finish. Proper preparation, including cleaning and repairing any imperfections, is essential for successful results.

How Long Does It Take for the Sealant to Fully Cure?

Like a watchful gardener waiting for seeds to sprout, you must allow the terrazzo sealant time to fully cure. Typically, it takes about 24 to 48 hours for the sealant to completely set and achieve maximum durability.

Can Terrazzo Be Polished in High-Traffic Areas?

Yes, terrazzo can be polished in high-traffic areas. Regular maintenance is crucial to uphold its shine and durability. Proper polishing techniques, like diamond grinding and sealing with quality products, are essential for long-lasting results.

What Is the Recommended Maintenance Routine for Polished Terrazzo?

To maintain polished terrazzo, regularly clean with a mild detergent and warm water. Avoid harsh chemicals that can damage the shine. Periodically reseal to protect the surface and restore luster. Consistent care ensures longevity.

Will Polishing Terrazzo Affect Its Slip Resistance?

Polishing terrazzo can enhance its appearance but might reduce slip resistance. To maintain safety, consider using anti-slip treatments or finishes after polishing. Consult with professionals to strike a balance between a glossy finish and slip resistance.