If you've noticed unsightly cracks and wear on your concrete driveway, it's essential to address them promptly to prevent further deterioration. Start by carefully evaluating the extent of the damage and preparing to take the necessary steps to restore your driveway to its former glory. By following a few straightforward procedures and using the right materials, you can revitalize your driveway and enhance its longevity. Let's guide you through the process of repairing your concrete driveway effectively, ensuring a durable and appealing finish that will stand the test of time.

Key Takeaways

Contents

- Assess damage by inspecting for cracks and discoloration.

- Gather materials like patching compound and sealer.

- Clean the driveway thoroughly before repairing.

- Fill cracks and holes with appropriate patching material.

- Apply concrete patch and sealer for a durable repair.

Assessing the Damage

When determining the extent of damage to your concrete driveway, begin by visually inspecting the surface for cracks, spalling, or discoloration.

Cracks can vary in width and depth, with wider or deeper cracks indicating more severe damage. Spalling, where small pieces of concrete have chipped off, is often a sign of freeze-thaw cycles or poor installation. Discoloration could be due to a variety of reasons such as oil spills, mold, or even underlying structural issues.

To accurately assess the damage, use a screwdriver or a similar tool to probe the depth of cracks or holes.

Take note of any areas where the concrete feels hollow or sounds different when tapped, as this could indicate a void beneath the surface. Additionally, check the edges of the driveway for crumbling or uneven sections that may need attention.

Gathering the Necessary Materials

Before you can proceed with repairing your concrete driveway, you will need to gather the necessary materials to effectively address the identified damage.

To ensure you have everything required for the repair task, refer to the table below for a comprehensive list of materials:

| Materials | Description | Quantity |

|---|---|---|

| Concrete Patching Compound | High-quality compound for filling cracks | Sufficient amount |

| Concrete Sealer | Protects the repaired area from moisture | 1 gallon |

| Protective Gear | Safety glasses, gloves, and a dust mask | 1 set |

| Trowel | For applying the patching compound smoothly | 1 |

Make sure to acquire the specified quantities of each material to guarantee a successful repair. The concrete patching compound is crucial for filling in the cracks, while the sealer will provide long-lasting protection. Additionally, wearing the proper protective gear is essential for your safety during the repair process. The trowel will help you apply the patching compound evenly for a professional finish.

Cleaning the Driveway Surface

To effectively prepare the concrete surface for repair, begin by thoroughly cleaning the driveway.

Start by sweeping the entire area to remove loose debris such as dirt, leaves, and rocks. Use a pressure washer with a high-powered nozzle to remove stubborn stains, mold, and mildew. Ensure that the driveway is completely dry before proceeding with any repairs.

Next, inspect the surface for any oil or grease stains. Apply a degreaser to these areas and scrub with a stiff brush to lift the stains.

Rinse thoroughly with water and allow the driveway to dry completely.

For efflorescence or mineral deposits, which appear as white, chalky residue, use a efflorescence remover following the manufacturer's instructions.

Rinse the driveway thoroughly after treatment.

Lastly, inspect the driveway for any remaining dirt or grime. Use a concrete cleaner or detergent specifically designed for driveways.

Scrub the surface with a brush or broom and rinse off with water. Once the driveway is clean and dry, you're ready to move on to the next step of repairing cracks and holes.

Filling in Cracks and Holes

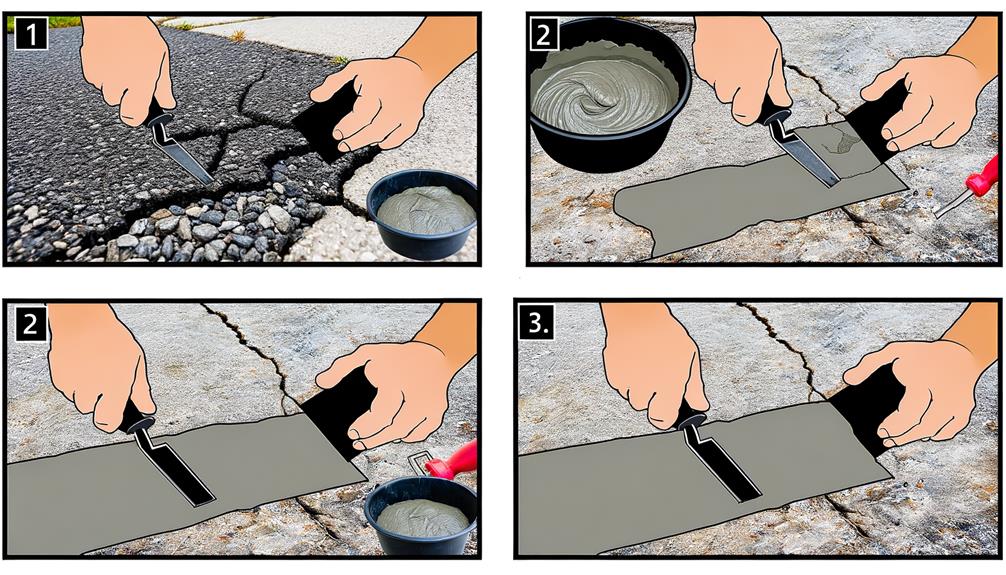

To effectively repair cracks and holes in your concrete driveway, it's crucial to start by selecting an appropriate concrete patching material that matches the composition of your driveway surface.

Begin by cleaning out any debris, dirt, or loose concrete from the cracks and holes using a wire brush and a shop vacuum.

For small cracks, a vinyl concrete patching compound can be used, while larger crevices may require a latex or polymer-modified cement patch. Ensure that the patching material is mixed to the right consistency as per the manufacturer's instructions.

Fill the cracks and holes with the patching material using a trowel, pressing it firmly into place and smoothing the surface evenly. Make sure to overfill the cracks slightly to compensate for shrinkage as the patch dries.

Allow the patched areas to dry completely before proceeding to the next steps in repairing your concrete driveway. Properly filling in cracks and holes is a crucial step in restoring the structural integrity and appearance of your driveway.

Applying a Concrete Patch

When applying a concrete patch to your driveway, start by preparing the surface by cleaning it thoroughly to ensure proper adhesion of the patching material. Here is a step-by-step guide to help you effectively apply a concrete patch:

| Step | Description |

|---|---|

| Clean the Surface | Remove any debris, dirt, or loose concrete from the area to be patched. Ensure the surface is clean and free of any contaminants. |

| Apply Bonding Agent | Use a bonding agent to enhance the adhesion between the existing concrete and the patching material. Follow the manufacturer's instructions for the proper application. |

| Mix and Apply Patch | Prepare the concrete patch mixture according to the manufacturer's guidelines. Apply the patch evenly and level it with the surrounding surface. Allow it to cure as per the recommended time before using the driveway. |

Finishing Touches and Maintenance

For a polished and durable finish to your concrete driveway repair project, attention to the finishing touches and ongoing maintenance is crucial.

Once the concrete patch has been applied and allowed to cure, it's essential to seal the surface to protect it from water penetration, chemicals, and wear. Choose a high-quality concrete sealer suitable for driveways and apply it evenly using a roller or sprayer.

Follow the manufacturer's instructions for the number of coats needed and drying times.

Regular maintenance is key to preserving the integrity of your repaired concrete driveway.

Inspect the surface periodically for any signs of cracking, spalling, or discoloration. Promptly address any issues that arise by applying a concrete patch or sealer as needed.

Additionally, keep the driveway clean by sweeping away debris and washing it with a mild detergent and water when necessary. Avoid using harsh chemicals that can damage the concrete.

Frequently Asked Questions

Can I Repair a Concrete Driveway in Cold Weather?

In cold weather, repairing a concrete driveway might be tricky. Ensure the surface is dry and free of ice. Use quick-setting concrete mix for faster results. Don't forget to cover the repaired area with a tarp to prevent freezing.

How Long Should I Wait Before Driving on the Repaired Driveway?

You should wait at least 24 to 48 hours before driving on the repaired driveway to ensure proper curing. Avoid heavy vehicles for the first week. Allow the concrete to fully set and strengthen before subjecting it to regular use.

Can I Use Regular Concrete for Patching Cracks?

When patching cracks in your driveway, regular concrete won't cut it. Opt for a specialized concrete mix designed for patching. This ensures proper adhesion and durability, preventing future issues. Invest in quality for lasting results.

Will Repairing My Driveway Increase My Property Value?

Repairing your driveway can increase property value by enhancing curb appeal and structural integrity. Ensure proper materials and techniques are used for long-lasting results. Consult with professionals to maximize value and avoid potential issues.

Is It Necessary to Seal a Repaired Concrete Driveway?

Just like a shield fortifies a knight, sealing a repaired concrete driveway safeguards against the elements. A crucial step, as it enhances durability, prevents water damage, and maintains the driveway's structural integrity for years to come.