If you've ever admired the sleek elegance of a polished concrete worktop in a contemporary kitchen, you might be wondering how to achieve the same stunning look in your own space. From selecting the right materials to mastering the finishing touches, the process of creating polished concrete worktops requires attention to detail and precision. By following a few key steps, you can transform a basic concrete slab into a sophisticated and durable surface that enhances the aesthetic appeal of your kitchen or bathroom.

Key Takeaways

Contents

- 1 Key Takeaways

- 2 Materials Needed

- 3 Preparation Steps

- 4 Pouring and Casting

- 5 Curing Process

- 6 Grinding and Polishing

- 7 Sealing and Maintenance

- 8 Frequently Asked Questions

- 8.1 Can Polished Concrete Worktops Be Customized With Colors or Patterns?

- 8.2 How Do I Prevent Cracking in My Concrete Worktops?

- 8.3 Is It Possible to Add Recycled Materials to the Concrete Mix?

- 8.4 Can I Install Undermount Sinks in Polished Concrete Worktops?

- 8.5 What Is the Average Lifespan of Polished Concrete Worktops?

- Use high-quality concrete mix designed for durability.

- Follow proper pouring techniques to prevent air bubbles.

- Maintain consistent moisture and temperature during curing.

- Gradually grind and polish the surface to a glossy finish.

- Seal the worktop with a quality sealer for protection.

Materials Needed

To create polished concrete worktops, you'll need a specific set of materials that are essential for achieving a professional finish.

Firstly, you must have high-quality concrete mix, preferably designed for countertops, to ensure durability and a smooth surface. You'll also require water and a concrete mixer to create the perfect consistency.

Metal trowels are essential for spreading and leveling the concrete evenly. Diamond polishing pads, ranging from coarse to fine grit, are crucial for achieving that glossy finish. It's imperative to have a wet polisher to attach the diamond pads for the polishing process.

Additionally, protective gear such as gloves, goggles, and a mask are necessary to ensure your safety when working with concrete and chemicals.

Lastly, a high-quality concrete sealer is vital to protect the worktops from stains and enhance their longevity. By meticulously selecting and utilizing these materials, you can master the art of creating flawless polished concrete worktops.

Preparation Steps

For preparing the concrete surface before applying the mix, it's crucial to ensure that the work area is clean and free from any debris.

Begin by thoroughly cleaning the worktop surface with a degreaser to remove any dirt, oil, or other contaminants. It's essential to repair any cracks or imperfections in the surface using a suitable concrete patching compound.

Once the surface is clean and repaired, apply a concrete bonding agent to ensure optimal adhesion of the concrete mix.

Next, carefully measure and mix the concrete according to the manufacturer's instructions, ensuring a smooth and consistent blend.

Use a trowel to spread the concrete evenly over the worktop surface, making sure to fill any gaps and create a level finish.

Allow the concrete to cure for the recommended time before proceeding to the polishing stage.

Proper preparation is key to achieving a flawless polished concrete worktop that's durable and visually appealing.

Pouring and Casting

Before proceeding with pouring and casting the concrete mix for your polished concrete worktop, ensure that all preparation steps have been meticulously completed.

The concrete mix should be a precise combination of cement, aggregates, and water. Use a high-quality concrete mix designed for countertops to ensure durability and strength. Measure the mix components carefully to maintain consistency and strength in the final product.

When pouring the concrete into the mold, do it slowly and steadily to prevent air bubbles from forming.

Vibrating the mold during pouring helps release any trapped air and ensures a smooth finish. Use a trowel to level the surface and remove excess concrete. Pay close attention to the edges and corners to ensure they're properly filled and reinforced.

After casting the concrete, cover it with plastic sheeting to prevent moisture loss during the curing process.

Let the concrete cure for the recommended time before proceeding with polishing. Following these steps meticulously will result in a high-quality polished concrete worktop that's both functional and visually appealing.

Curing Process

Ensure that the freshly poured concrete worktop is protected and maintained carefully during the curing process. Curing is a critical stage that directly impacts the strength and durability of your polished concrete worktop. Follow these essential steps to achieve optimal curing results:

| Curing Process | Description | Time Required |

|---|---|---|

| Initial Cure | Keep the worktop covered with plastic sheeting to retain moisture. | 24 hours |

| Moisture Control | Maintain a damp environment by misting the surface regularly. | 7 days |

| Temperature | Ensure the worktop is kept at a consistent temperature range of 50-75°F (10-24°C). | Throughout curing process |

| Air Circulation | Allow for proper ventilation to prevent moisture buildup. | Throughout curing process |

| Protection | Avoid placing heavy objects on the worktop during curing. | Throughout curing process |

Grinding and Polishing

When it comes to achieving a flawless finish on your polished concrete worktop, the grinding and polishing process plays a crucial role.

To start, ensure the concrete has cured adequately before beginning this phase. Begin with a coarse grinding disk to level the surface and remove any imperfections.

Gradually progress to finer grits to refine the surface and achieve the desired smoothness. Pay close attention to the edges and corners, as they require special care to match the overall finish.

During the polishing stage, use resin-bonded diamond disks to bring out the concrete's natural shine.

Work methodically, moving from lower to higher grits to enhance the luster. Keep the surface wet to prevent dust and ensure a uniform finish.

As you progress, inspect the surface regularly for any blemishes or uneven areas that need further attention. The key to a perfect polished concrete worktop lies in the meticulous grinding and polishing process, where precision and expertise are paramount.

Sealing and Maintenance

To maintain the impeccable finish of your polished concrete worktop, sealing and regular maintenance are essential components of proper care.

Sealing your polished concrete worktop is crucial to protect it from stains, spills, and wear. Choose a high-quality concrete sealer that's specifically designed for polished surfaces. Apply the sealer according to the manufacturer's instructions, ensuring thorough coverage and allowing sufficient drying time between coats.

Regularly inspect the worktop for any signs of wear or damage, and promptly address any issues to prevent further deterioration.

When it comes to maintenance, clean your polished concrete worktop regularly with a mild detergent and water.

Avoid harsh chemicals or abrasive cleaners that can damage the surface. Consider using pH-neutral cleaners to maintain the shine and longevity of your worktop.

In high-traffic areas, consider resealing your worktop every 1-3 years to ensure continued protection and durability.

Frequently Asked Questions

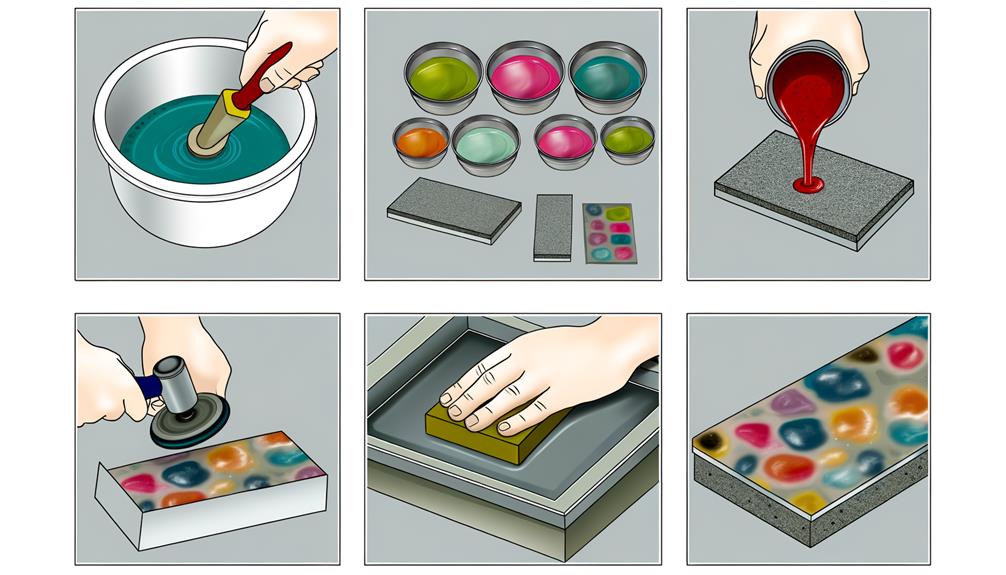

Can Polished Concrete Worktops Be Customized With Colors or Patterns?

Yes, polished concrete worktops can indeed be customized with a variety of colors and patterns. This allows you to achieve a unique look that suits your style preferences and complements your overall design aesthetic effectively.

How Do I Prevent Cracking in My Concrete Worktops?

To prevent cracking in your concrete worktops, ensure proper reinforcement with steel mesh or fibers. Control the water-to-cement ratio for optimal strength. Use plasticizers to enhance workability. Properly cure the concrete with moisture and cover to avoid rapid drying.

Is It Possible to Add Recycled Materials to the Concrete Mix?

Want to enhance sustainability in your concrete worktops? Yes, you can add recycled materials to the mix. Ensure proper proportions to maintain structural integrity. Experiment with different ratios for a unique and eco-friendly design.

Can I Install Undermount Sinks in Polished Concrete Worktops?

Yes, you can install undermount sinks in polished concrete worktops. Ensure precise measurements for a seamless fit. Use specialized tools for accurate cutting and secure installation. Follow detailed instructions for proper sealing to maintain the integrity of the worktop.

What Is the Average Lifespan of Polished Concrete Worktops?

On average, polished concrete worktops can last for decades when properly maintained. Regular sealing and care are essential to ensure their longevity. Following manufacturer guidelines and professional advice will help you maximize their lifespan.