When comparing epoxy resin and regular resin, did you know that epoxy resin typically offers over twice the strength of regular resin formulations? This significant difference in strength can have a substantial impact on the durability and longevity of your project. Understanding the key disparities between these two types of resins is crucial for selecting the most suitable option for your specific needs. Let's explore the nuances that set epoxy resin apart from regular resin and how these distinctions can influence the success of your next endeavor.

Key Takeaways

Contents

- Epoxy resin has higher strength, adhesion, and chemical resistance than regular resin.

- Epoxy resin exhibits lower shrinkage during curing, ideal for precise dimensional stability.

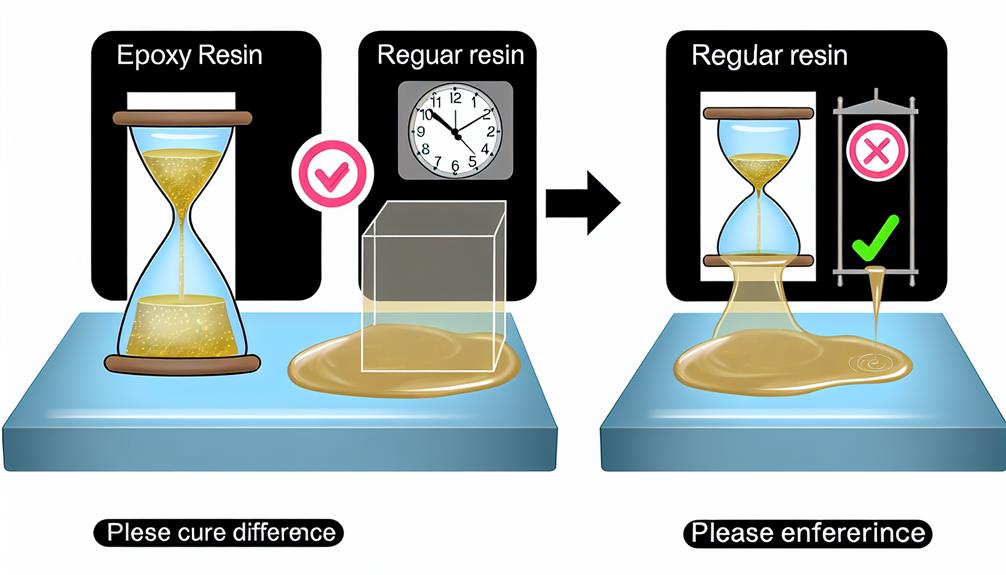

- Epoxy resin cures through a chemical reaction, while regular resin cures through evaporation.

- Epoxy resin offers better durability and longevity compared to regular resin.

- Epoxy resin excels in tensile and flexural strength, while regular resin may have better impact resistance.

Composition Variances

When comparing epoxy resin to regular resin, one of the key differences lies in their composition variances.

Epoxy resin is a thermosetting polymer formed by mixing epoxide resin with a curing agent, which triggers a chemical reaction resulting in a hardened material.

On the other hand, regular resin, commonly known as polyester resin, is a thermosetting polymer produced by the reaction of dibasic organic acids with polyhydric alcohols.

The distinct chemical structures of these resins lead to variations in their properties.

Epoxy resin tends to have higher strength, better adhesion, and chemical resistance compared to regular resin. Additionally, epoxy resin exhibits lower shrinkage during curing, making it ideal for applications requiring precise dimensional stability.

Regular resin, while less expensive, may be more prone to cracking and shrinking.

Understanding the composition variances between epoxy and regular resin is crucial in selecting the appropriate material for specific projects based on desired properties and performance requirements.

Curing Process Disparities

During the curing process, epoxy resin and regular resin exhibit notable disparities in their mechanisms and outcomes.

Epoxy resin cures through a chemical reaction between the resin and hardener components. This reaction is exothermic, meaning it generates heat, leading to a faster and more controlled curing process.

In contrast, regular resin typically cures through a process of evaporation, where the solvent in the resin evaporates, leaving the solid components behind to harden. This curing method is slower and can be affected by environmental factors like temperature and humidity.

Epoxy resin curing results in a strong, durable final product with excellent adhesion and resistance properties.

Regular resin, while still producing a solid final product, may have a tendency to shrink during the curing process, potentially leading to cracks or other imperfections.

Understanding these curing process disparities is crucial for selecting the right resin for your specific application needs.

Application Distinctions

In applications where structural strength and durability are paramount, epoxy resin emerges as the preferred choice due to its superior bonding capabilities and resistance properties.

Epoxy resin is renowned for its ability to form strong adhesive bonds with various materials, making it ideal for applications requiring a high level of structural integrity. Its excellent resistance to chemicals, heat, and moisture further enhances its suitability for demanding environments.

When compared to regular resin, epoxy resin offers enhanced durability and longevity, making it a top choice for projects where longevity is crucial.

Moreover, the application process for epoxy resin requires precise mixing ratios and thorough mixing to ensure optimal performance.

This meticulous approach is necessary to activate the resin's curing process effectively, resulting in a strong and durable final product. On the other hand, regular resin may be more forgiving in terms of mixing ratios and application techniques but may not offer the same level of strength and durability as epoxy resin.

Ultimately, for applications requiring superior bonding strength and resistance properties, epoxy resin stands out as the preferred option.

Strength Variations

Moving from the discussion on application distinctions, the focus now shifts to examining the strength variations between epoxy resin and regular resin.

Understanding the differences in strength can greatly impact the choice of resin for your specific project needs.

Below are some key strength variations to consider:

- Tensile Strength:

- Epoxy resin typically has a higher tensile strength compared to regular resin.

This means it can withstand greater forces pulling it apart without breaking.

2. Flexural Strength:

– Epoxy resin also excels in flexural strength, making it more resistant to bending without fracturing.

This property is crucial for projects requiring durability and stability over time.

3. Impact Strength:

– Regular resin may have better impact strength than epoxy resin, meaning it can absorb sudden shocks better without cracking.

This factor is vital in projects where impact resistance is a priority, such as in certain types of coatings or molds.

Considering these strength variations is essential in determining which type of resin is best suited for your specific project requirements.

Project Suitability

Considering the specific demands and characteristics of your project, determining the most suitable resin is paramount.

Epoxy resin offers exceptional strength and durability, making it ideal for projects requiring a high level of robustness. Its ability to resist chemicals, heat, and moisture makes it perfect for applications such as marine coatings, flooring, and crafting durable furniture.

Regular resin, on the other hand, is more flexible and may be better suited for projects that require a degree of elasticity, like flexible molds or certain types of jewelry.

When choosing between epoxy resin and regular resin for your project, it's crucial to assess the specific requirements of the task at hand. If strength and durability are your primary concerns, epoxy resin is likely the superior choice.

However, if flexibility and moldability are more important, regular resin may be the better option. Understanding the unique properties and characteristics of each type of resin will ensure that your project is executed with precision and meets all necessary specifications.

Frequently Asked Questions

Can Epoxy Resin Be Used Outdoors?

Yes, epoxy resin can be used outdoors due to its high durability and resistance to UV rays. However, it's crucial to choose a UV-resistant epoxy and apply a protective topcoat to ensure long-lasting results in outdoor settings.

Is Regular Resin Food-Safe?

Regular resin is generally not food-safe due to its porosity, which can harbor bacteria and chemicals. When used for food-related items, always coat with a food-safe sealant or opt for food-grade resin.

Do Epoxy and Regular Resins Have a Strong Odor?

Yes, both epoxy and regular resins emit a strong odor during curing due to the chemical reactions involved. Ventilation is crucial to minimize exposure. Epoxy generally has a stronger smell than regular resin, impacting user experience.

Can Epoxy Resin Be Used for Jewelry Making?

Yes, epoxy resin can be used for jewelry making. It offers durability, clarity, and a glossy finish, ideal for preserving delicate items. Its self-leveling properties make it perfect for creating intricate designs. Ensure proper ventilation due to its strong odor.

Are There Any Safety Precautions Specific to Handling Regular Resin?

When handling regular resin, ensure proper ventilation to avoid inhaling fumes. Always wear protective gear like gloves and eyewear. Be cautious with skin contact as resin can cause irritation. Follow manufacturer's instructions for safe usage.